MV-UD

MV-UD Power

THE LS MV-UD ADVANTAGE:

LS Cable & System USA has designed and is utilizing a proprietary system which sets a new standard for clean material handling in the industry. Used on MV-90, and MV-105 cable LS SureCleanTM Isolator Technology ensures minimum environmental exposure through customized material handling, isolator technology and a gravity conveyance system. By reducing excessive ionic and particulate contamination, cables maintain their integrity for a much longer life cycle. LS SureCleanTM is certified ISO 5 (Class 100) and is used on all MV products we produce. Access the white paper here.

LS Cable & System USA has designed and is utilizing a proprietary system which sets a new standard for clean material handling in the industry. Used on MV-90, and MV-105 cable LS SureCleanTM Isolator Technology ensures minimum environmental exposure through customized material handling, isolator technology and a gravity conveyance system. By reducing excessive ionic and particulate contamination, cables maintain their integrity for a much longer life cycle. LS SureCleanTM is certified ISO 5 (Class 100) and is used on all MV products we produce. Access the white paper here.

LS Cable & System USA EZ-RFTM Reduced Friction coating is water-based, colorless, non-staining and contains no VOCs used across all MV-90 and MV-105 Cable. Choose it for any LS Cable & System USA product we offer. Cable with this silicone-free dry lubricant arrives pre-lubricated, replaces messy field-applied lubricants, offers additional weather- and UV-resistance, and reduces friction up to 85%*. EZ-RF allows you to run cable and wire faster and get more from every pull and push, and lower project costs.

At twice the ampacity per pound, not only is aluminum more cost-effective than copper, it is easier to work with in more confined spaces. In today’s tough economy, it is crucial to cut costs while considering the environmental impact of building material choices. By including our aluminum cable in your project specifications, the savings you realize can be used to defray the cost of energy-saving devices and accelerate the payback of your project.

The process of all three extrusions in one process (True Triple) enables LS Cable & System USA to produce high-quality cable, guaranteeing precise dimensional tolerances and meeting customer specifications. When compared with tandem single (1+1+1) and dual extrusion (1+2) systems, True Triple extrusion significantly reduces the possibility of foreign material particulates entering the three insulation layers, thus reducing the incidence of voltage and partial discharge failures.

We stand behind our products with a 100% satisfaction guarantee. LS Group has executed projects in 50 countries in America, Asia and the Middle East. Our access to the global LS network means if we don’t have what you need, we can get it. LS group’s full line-up of energy distribution products guarantees an optimized solution for each project. Trust our products have been engineered to last and will perform as expected — with a warranty that backs it up.

We stand behind our products with a 100% satisfaction guarantee. LS Group has executed projects in 50 countries in America, Asia and the Middle East. Our access to the global LS network means if we don’t have what you need, we can get it. LS group’s full line-up of energy distribution products guarantees an optimized solution for each project. Trust our products have been engineered to last and will perform as expected — with a warranty that backs it up.

- TR-XLPE/CN/LLDPE Power, MV-90 Type Primary UD, 15kV–35kV

- TR-XLPE/CN/LLDPE Power, MV-90 Type Primary UD, 15kV–35kV (Solid)

- TR-XLPE/CN/XLPE Power, MV-105 Type Primary UD, 15kV-35kV

- TR-XLPE/CN/LLDPE Power, MV-90 Type Primary UD, 15kV–35kV (Cu)

- EPR/CN/LLDPE Power, MV-90 Type Primary UD, 15kV–35kV

- EPR/CN/LLDPE Power, MV-90 Type Primary UD, 15kV–35kV (Solid)

- EPR/CN/LLDPE Power, Type MV-90 Primary UD, 15kV–35kV (Cu)

Series U

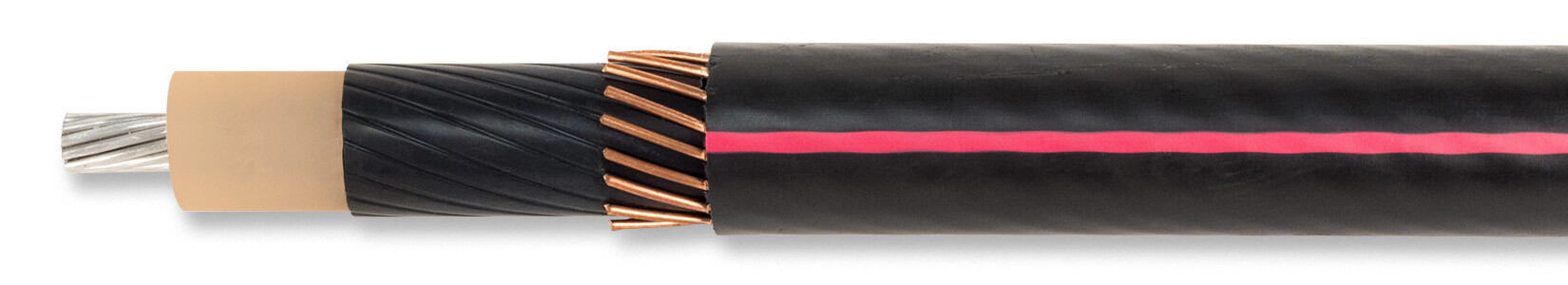

The Medium Voltage Underground Distribution (UD) cables consist of an Aluminum (filled or unfilled) conductor, covered with tree-retardant cross-linked polyethylene (TR-XLPE), a concentric neutral of helically applied copper wires, and a linear low‑density polyethylene (LLDPE) jacket with 3 extruded red stripes.

Applications

- Suitable for underground primary power applications

- For wet or dry locations

- For direct burial or in duct

Series U

Medium Voltage Underground Distribution (UD) cable consists of an Aluminum Solid conductor, covered with tree-retardant crosslinked polyethylene (TR-XLPE), a concentric neutral of helically applied copper wires, and a linear low-density polyethylene (LLDPE) jacket with 3 extruded red stripes.

Applications

- Suitable for underground primary power applications

- For wet or dry locations

- For direct burial or in duct

Series U

Medium Voltage Underground Distribution (UD) cable consists of an Aluminum stranded conductor, (filled or unfilled) covered with tree retardant cross-linked polyethylene (TR-XLPE), a concentric neutral of helically applied copper wires, and a cross-linked (filled or unfilled) polyethylene (XLPE) jacket with 3 extruded cross-linked red stripes.

Applications

- Suitable for underground primary power applications

- For wet or dry locations

- For direct burial or in duct

Series U

Medium Voltage Underground Distribution (UD) cable consists of an Aluminum (filled or unfilled) conductor, covered with ethylene propylene rubber (EPR), a concentric neutral of helically applied copper wires, and a linear low-density polyethylene (LLDPE) jacket with 3 extruded red stripes.

Applications

- Suitable for underground primary power applications

- For wet or dry locations

- For direct burial or in duct

Series U

The Medium Voltage Underground Distribution (UD) cables consist of an Aluminum (filled or unfilled) conductor, covered with ethylene propylene rubber (EPR), a concentric neutral of helically applied copper wires, and a linear low-density polyethylene (LLDPE) jacket with 3 extruded red stripes.

Applications

- Suitable for underground primary power applications

- For wet or dry locations

- For direct burial or in duct

Series U

The Medium Voltage Underground Distribution (UD) cables consist of an Aluminum Solid conductor, covered with ethylene propylene rubber (EPR), a concentric neutral of helically applied copper wires, and a linear low-density polyethylene (LLDPE) jacket with 3 extruded red stripes.

Applications

- Suitable for underground primary power applications

- For wet or dry locations

- For direct burial or in duct

Series U

The Medium Voltage Underground Distribution (UD) cables consist of a Copper (filled or unfilled) conductor, covered with ethylene propylene rubber (EPR), a concentric neutral of helically applied copper wires, and a linear low-density polyethylene (LLDPE) jacket with 3 extruded red stripes.

Applications

- Suitable for underground primary power applications

- For wet or dry locations

- For direct burial or in duct