Automotive Cable Solutions

Your Trusted Automotive Cable Supplier

Automotive Projects

LS Cable & System USA brings proven automotive project experience across a range of applications and facility needs. Browse the examples below or view the complete project list.

Product Line Up

LS Cable & System USA's line of LV and MV solutions help power the automotive industry from grid to charging station and beyond.

Ex-Way (UL) Low-Voltage Busway

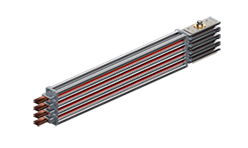

Data-Way (UL) Low/Medium-Voltage Busway

The system supports up to 6,300 A and 690 V, with optional medium-voltage configurations available. Its plug-and-play tap-off boxes enable flexible, high-density power feeds—ideal for powering robotic cells, conveyor systems, and workstations. Designed for excellent heat dissipation and unmatched modularity, it delivers reliable, adaptable performance in demanding environments.

MV-105

Great for MV runs between substations and equipment rooms

Aluminum Interlock Armored (AIA)

This rugged 600 V control and power cable (Type MC) features UL-approved triple-extruded insulation for dependable performance. Its EZ-RF reduced-friction coating streamlines long cable pulls, making it ideal for equipment retrofits or conveyor runs. Manufactured in a clean “SureClean™” ISO 5 environment, it ensures maximum reliability in critical control applications.

|

Feature |

Ex-Way |

Data-Way |

MV 105 |

AIA Cable |

|

Voltage Range |

600 V |

To 690 V (LV) / MV option |

|

600 V |

|

Scalability |

High modularity |

Tap-off flexibility |

|

Flexible long runs |

|

Application Fit |

Retrofit & expansion |

Feeding power-intensive cells |

|

Control/power to machinery |

|

Durability |

NEMA-rated, earthquake-resistant |

IP-rated, reliable joints |

|

Weather/UV-resistant insulated MC |

Why Silicone-Free?

Our cable and wire is free of both silicone and PFAS "forever" chemicals. Silicone-free cable is critically important for the automotive industry for several reasons:

Paint Compatibility (Low VOC Emissions)

Silicone-based materials can release volatile organic compounds (VOCs) that cause defects in automotive paint finishes. Silicone contamination leads to "fish eyes" or cratering, making silicone-free cables essential in automotive manufacturing environments.

Improved Adhesion for Sealants and Coatings

Many adhesives, coatings, and sealants used in automotive assembly do not bond well to surfaces contaminated with silicone residues. Using silicone-free cables helps maintain the integrity of these processes.

Thermal and Chemical Resistance

Modern silicone-free cable materials, such as cross-linked polyolefin or fluoropolymers, provide excellent resistance to high temperatures, oils, fuels, and other automotive chemicals without the risk of silicone degradation.

Regulatory and Environmental Compliance

Some automotive manufacturers and suppliers adhere to strict regulations limiting silicone use due to its impact on production processes and potential environmental concerns.

Cost and Durability

Silicone-free cables can be more cost-effective and durable in automotive environments, where exposure to mechanical stress, abrasion, and temperature fluctuations is common.

Let's Connect

LS Cable & System USA is here to help power your next automotive project. Ready to take the next step? Submit your information to get started.